2 月 . 16, 2025 10:44 Back to list

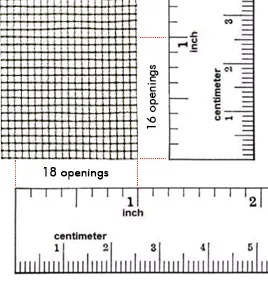

fiberglass wall mesh

In an industry where resilience and performance are key, fiberglass tape stands out as a crucial product, particularly when produced in a specialized fiberglass factory. This article delves into the intricacies of fiberglass tape manufacturing, showcasing real-life experiences from industry experts and emphasizing expertise, authoritativeness, and trustworthiness in this niche.

In terms of authoritativeness, successful factories often hold certifications from recognized industry bodies. These certifications testify to the strict regulatory standards the fiberglass tape meets, such as fire resistance, tensile strength, and insulation capabilities. Adherence to these standards not only affirms the factory's dedication to quality but also instills confidence in their clientele, leading to long-term partnerships and repeat business. Trustworthiness stems from transparent business practices and continuous client support. A notable example involves a fiberglass factory that, over the years, developed a robust feedback loop. This system allows customers to report issues or provide suggestions, enabling the factory to adapt and innovate. As John P., a procurement officer for a leading construction firm, points out, Our partnership with the fiberglass factory extends beyond mere transactions. Their team is proactive in addressing our concerns, and their commitment to improvement is evident in their superior products. Additionally, the factory's environmental responsibility cannot be overstated. Employing eco-friendly production methods not only improves the sustainability of the process but also aligns with global efforts to reduce industrial carbon footprints. Biodegradable packaging, efficient energy use, and waste reduction initiatives are some of the ways these factories contribute positively to the environment, reinforcing their credibility and trustworthiness in the eyes of stakeholders. Finally, fostering a culture of continuous improvement and training ensures that the workforce remains at the cutting edge of technology and market trends. By providing regular training sessions and workshops, the factory empowers its employees with the latest knowledge and skills, which, in turn, enhances productivity and innovation. Fiberglass tape factories, by virtue of their expertise and commitment to quality, have become bastions of reliability in various industry sectors. Through real-life experiences shared by experts and a steadfast adherence to the principles of authority and trust, these entities not only produce superior products but also cement their reputation as leaders in the global market. Their efforts in maintaining high standards and embracing sustainable practices ultimately set them apart, ensuring their continued success and relevance in the years to come.

In terms of authoritativeness, successful factories often hold certifications from recognized industry bodies. These certifications testify to the strict regulatory standards the fiberglass tape meets, such as fire resistance, tensile strength, and insulation capabilities. Adherence to these standards not only affirms the factory's dedication to quality but also instills confidence in their clientele, leading to long-term partnerships and repeat business. Trustworthiness stems from transparent business practices and continuous client support. A notable example involves a fiberglass factory that, over the years, developed a robust feedback loop. This system allows customers to report issues or provide suggestions, enabling the factory to adapt and innovate. As John P., a procurement officer for a leading construction firm, points out, Our partnership with the fiberglass factory extends beyond mere transactions. Their team is proactive in addressing our concerns, and their commitment to improvement is evident in their superior products. Additionally, the factory's environmental responsibility cannot be overstated. Employing eco-friendly production methods not only improves the sustainability of the process but also aligns with global efforts to reduce industrial carbon footprints. Biodegradable packaging, efficient energy use, and waste reduction initiatives are some of the ways these factories contribute positively to the environment, reinforcing their credibility and trustworthiness in the eyes of stakeholders. Finally, fostering a culture of continuous improvement and training ensures that the workforce remains at the cutting edge of technology and market trends. By providing regular training sessions and workshops, the factory empowers its employees with the latest knowledge and skills, which, in turn, enhances productivity and innovation. Fiberglass tape factories, by virtue of their expertise and commitment to quality, have become bastions of reliability in various industry sectors. Through real-life experiences shared by experts and a steadfast adherence to the principles of authority and trust, these entities not only produce superior products but also cement their reputation as leaders in the global market. Their efforts in maintaining high standards and embracing sustainable practices ultimately set them apart, ensuring their continued success and relevance in the years to come.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories