2 月 . 16, 2025 12:01 Back to list

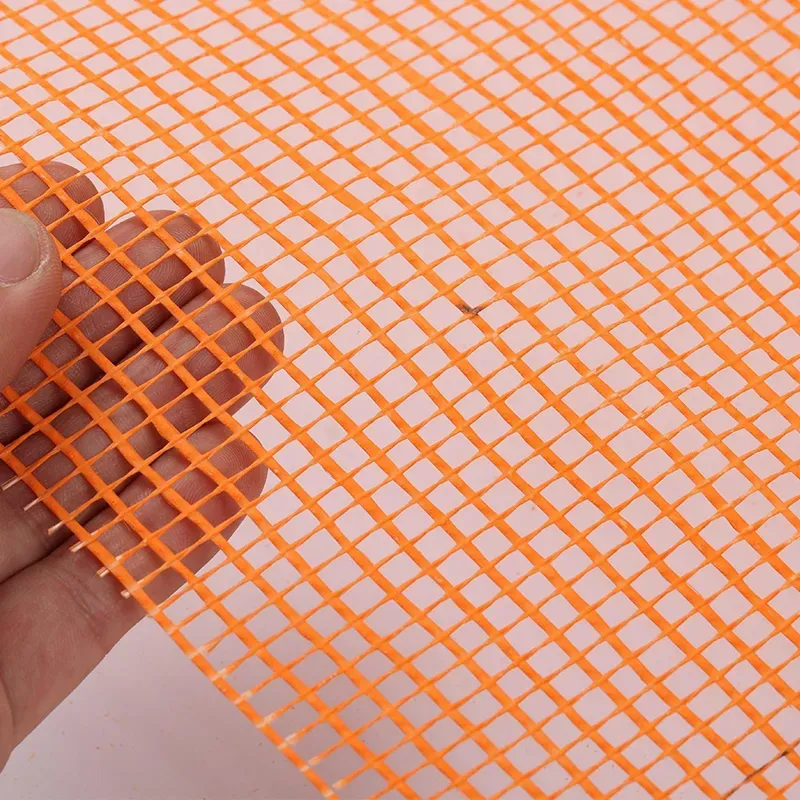

fiberglass wall mesh

In the evolving world of construction and industrial applications, fiberglass tape has emerged as a crucial component, offering unparalleled strength and versatility. Fiberglass tape manufacturers are continuously pushing the boundaries to innovate and cater to the diverse needs of various sectors. This article aims to provide a comprehensive look at the nuances of fiberglass tape manufacturing, ensuring that customers understand the sheer depth of quality and expertise involved in the process.

Trustworthiness extends beyond product quality; it encompasses customer service and post-purchase support. Reputable manufacturers create robust quality control processes, engaging in rigorous testing to guarantee that each batch of tape meets industry standards such as ISO 9001. This includes meticulous inspections for defects, tensile strength testing, and thermal resistance evaluations. Moreover, many manufacturers offer customization services, allowing clients to specify tape width, weave patterns, and coatings to suit specific project needs. This level of customization exemplifies a manufacturer’s dedication to customer satisfaction and reliability. The communication channel between clients and manufacturers is paramount for fostering trust. Manufacturers provide technical support and consultation services, helping clients select the appropriate type of fiberglass tape for their projects. Transparent communication about product specifications, manufacturing processes, and delivery timelines ensures that clients are well-informed, leading to efficient project planning and execution. The environmental impact of manufacturing processes is a growing concern worldwide, and fiberglass tape manufacturers are responding with sustainable practices. Many have initiated recycling programs for waste materials and invested in energy-efficient production methods. The endeavor to minimize environmental footprints illustrates a manufacturer’s comprehensive approach to corporate responsibility and social accountability. In conclusion, the world of fiberglass tape manufacturing is defined by diligence, precision, and a relentless pursuit of excellence. Leading manufacturers exemplify these qualities through their sophisticated production techniques, unwavering commitment to quality, and robust customer support services. By continuously innovating and adhering to the highest standards, these manufacturers solidify their positions as leaders in the industry. Understanding this meticulous process not only underscores the value of fiberglass tape but also establishes a benchmark for what clients should expect in terms of quality and service. The intricate balance of engineering expertise, authoritative commitment, and trustworthy practices positions top fiberglass tape manufacturers as indispensable partners in industrial and construction projects around the globe.

Trustworthiness extends beyond product quality; it encompasses customer service and post-purchase support. Reputable manufacturers create robust quality control processes, engaging in rigorous testing to guarantee that each batch of tape meets industry standards such as ISO 9001. This includes meticulous inspections for defects, tensile strength testing, and thermal resistance evaluations. Moreover, many manufacturers offer customization services, allowing clients to specify tape width, weave patterns, and coatings to suit specific project needs. This level of customization exemplifies a manufacturer’s dedication to customer satisfaction and reliability. The communication channel between clients and manufacturers is paramount for fostering trust. Manufacturers provide technical support and consultation services, helping clients select the appropriate type of fiberglass tape for their projects. Transparent communication about product specifications, manufacturing processes, and delivery timelines ensures that clients are well-informed, leading to efficient project planning and execution. The environmental impact of manufacturing processes is a growing concern worldwide, and fiberglass tape manufacturers are responding with sustainable practices. Many have initiated recycling programs for waste materials and invested in energy-efficient production methods. The endeavor to minimize environmental footprints illustrates a manufacturer’s comprehensive approach to corporate responsibility and social accountability. In conclusion, the world of fiberglass tape manufacturing is defined by diligence, precision, and a relentless pursuit of excellence. Leading manufacturers exemplify these qualities through their sophisticated production techniques, unwavering commitment to quality, and robust customer support services. By continuously innovating and adhering to the highest standards, these manufacturers solidify their positions as leaders in the industry. Understanding this meticulous process not only underscores the value of fiberglass tape but also establishes a benchmark for what clients should expect in terms of quality and service. The intricate balance of engineering expertise, authoritative commitment, and trustworthy practices positions top fiberglass tape manufacturers as indispensable partners in industrial and construction projects around the globe.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories