2 月 . 16, 2025 10:05 Back to list

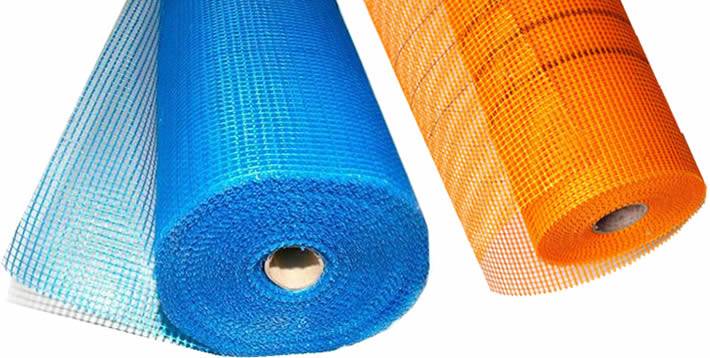

fiberglass wall mesh

Finding the right fiberglass tape supplier is crucial for ensuring high-quality outcomes in your projects, whether they're related to construction, marine applications, or industrial insulation. Through my extensive experience in the field of materials sourcing and an in-depth understanding of professional needs, here’s a firsthand account of the considerations and criteria that can guide you to a reliable supplier for fiberglass tape.

In an industry that continually evolves with technological advancements, working with an innovative supplier means staying ahead of the curve. Many of the leading suppliers invest significantly in R&D, creating new and improved versions of fiberglass tape that enhance strength, ease of application, and environmental sustainability. By choosing a supplier dedicated to innovation, you can ensure that your projects benefit from cutting-edge materials that offer improved performance and perhaps lower carbon footprints. Customer-Centric Approach The best fiberglass tape suppliers adopt a customer-centric approach, prioritizing customer satisfaction above all. This involves responsive customer service, comprehensive technical support, and post-purchase follow-ups. Suppliers who take time to understand client needs tend to provide customized solutions that fit specific project parameters. Furthermore, their ability to offer expert technical guidance reflects a mastery in the domain and significantly adds to their trustworthiness. Evaluated Track Record and Community Reputation Trustworthy suppliers often have an evaluated track record and are well-regarded within industry communities. Reputation can be a robust indicator of reliability and performance quality, reflecting years of consistent service and client satisfaction. Engaging with online forums, attending industry events, or consulting trade publications can provide insights into a supplier’s standing and help determine who is widely trusted among your peers. Rigorous Testing for Reliability Lastly, reliable fiberglass tape suppliers ensure their products go through rigorous testing phases before reaching the market. Look for those who showcase their testing processes and results, signifying their commitment to reliability and safety. Compliance with safety standards is non-negotiable in applications where the integrity of fiberglass tape directly influences the outcome of a task, such as in critical sealing applications in aerospace or marine environments. In conclusion, selecting the right fiberglass tape supplier involves a comprehensive evaluation of their quality standards, supply chain expertise, product versatility, commitment to innovation, customer-focused service, industry reputation, and testing rigor. Through the fusion of these elements, you secure a partnership that not only meets project specifications but aligns with your standards for excellence, reliability, and trustworthiness. Remember, the supplier's role extends beyond providing materials; they are collaborators in ensuring the success and safety of your projects. Choose wisely, and your projects will thank you for it.

In an industry that continually evolves with technological advancements, working with an innovative supplier means staying ahead of the curve. Many of the leading suppliers invest significantly in R&D, creating new and improved versions of fiberglass tape that enhance strength, ease of application, and environmental sustainability. By choosing a supplier dedicated to innovation, you can ensure that your projects benefit from cutting-edge materials that offer improved performance and perhaps lower carbon footprints. Customer-Centric Approach The best fiberglass tape suppliers adopt a customer-centric approach, prioritizing customer satisfaction above all. This involves responsive customer service, comprehensive technical support, and post-purchase follow-ups. Suppliers who take time to understand client needs tend to provide customized solutions that fit specific project parameters. Furthermore, their ability to offer expert technical guidance reflects a mastery in the domain and significantly adds to their trustworthiness. Evaluated Track Record and Community Reputation Trustworthy suppliers often have an evaluated track record and are well-regarded within industry communities. Reputation can be a robust indicator of reliability and performance quality, reflecting years of consistent service and client satisfaction. Engaging with online forums, attending industry events, or consulting trade publications can provide insights into a supplier’s standing and help determine who is widely trusted among your peers. Rigorous Testing for Reliability Lastly, reliable fiberglass tape suppliers ensure their products go through rigorous testing phases before reaching the market. Look for those who showcase their testing processes and results, signifying their commitment to reliability and safety. Compliance with safety standards is non-negotiable in applications where the integrity of fiberglass tape directly influences the outcome of a task, such as in critical sealing applications in aerospace or marine environments. In conclusion, selecting the right fiberglass tape supplier involves a comprehensive evaluation of their quality standards, supply chain expertise, product versatility, commitment to innovation, customer-focused service, industry reputation, and testing rigor. Through the fusion of these elements, you secure a partnership that not only meets project specifications but aligns with your standards for excellence, reliability, and trustworthiness. Remember, the supplier's role extends beyond providing materials; they are collaborators in ensuring the success and safety of your projects. Choose wisely, and your projects will thank you for it.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories