2 月 . 03, 2025 00:37 Back to list

using fiberglass tape supplier

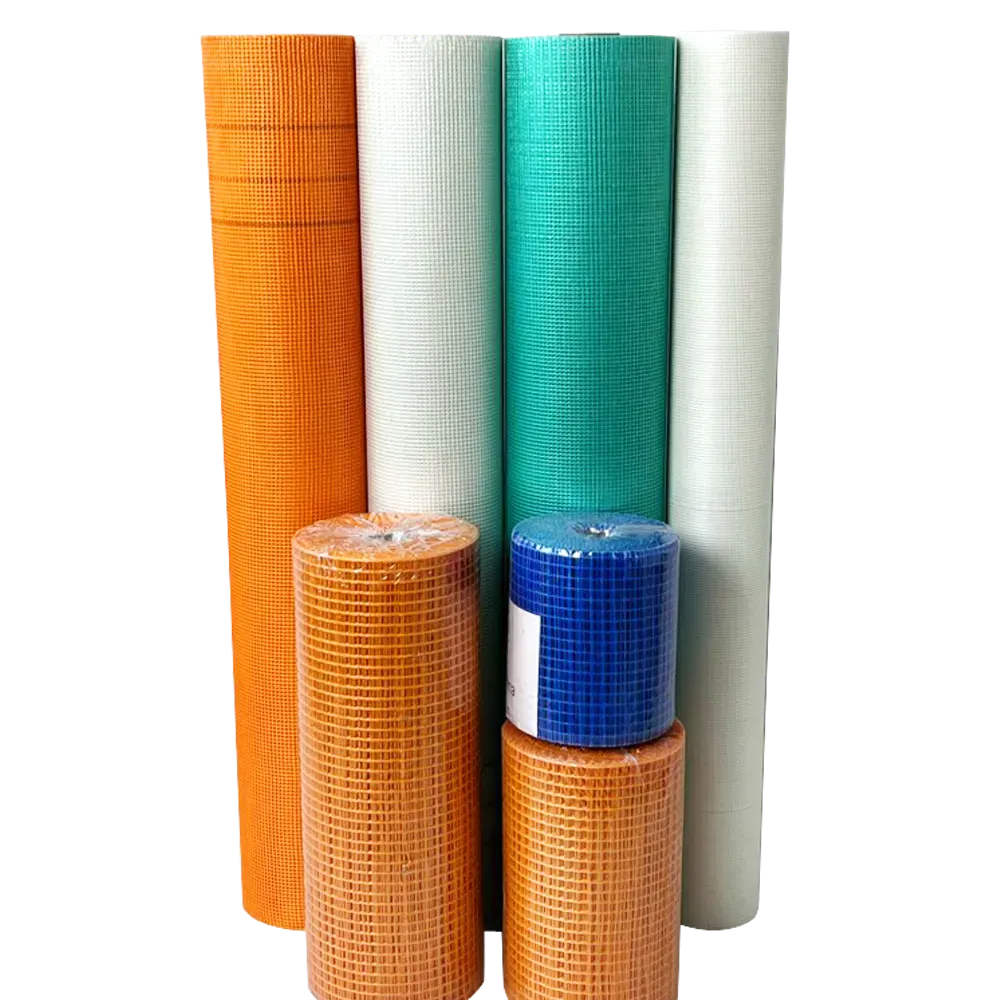

Navigating the landscape of finding a reliable fiberglass tape supplier involves numerous considerations to ensure quality, durability, and efficient supply chain logistics. For businesses entrenched in manufacturing, construction, or automotive industries, selecting the right supplier is critical, as this choice directly impacts project outcomes and operational success.

Assessing Reliability Reliability of supply chain performance also plays a key role in selecting a fiberglass tape supplier. Suppliers should exhibit a robust logistics framework, capable of ensuring timely deliveries and handling large volume demands efficiently. Evaluating their customer service response times and problem-resolution strategies can provide insights into their operational reliability. Building Trust through Transparency Trust in a supplier can be cultivated through their transparency in production processes and pricing. Trustworthy suppliers offer comprehensive product data sheets, openly share their supply chain processes, and provide clear, no-hidden-fees pricing models. Transparent practices allow businesses to forecast expenses accurately and plan procurement without unexpected financial hiccups. Customer Testimonials and Reviews Exploring customer reviews and testimonials provides a deeper understanding of a supplier's market reputation. Feedback from other businesses can shed light on the quality of the products, the supplier’s service response times, and overall customer satisfaction. Engaging with a supplier’s existing customers if possible can offer candid insights that aren’t always captured in written reviews. In summary, selecting a fiberglass tape supplier involves assessing their expertise, reliability, and trustworthiness. By focusing on these elements, businesses can ensure a steady supply of high-quality materials that meet project requirements and industry standards. A supplier that exhibits authority in the field through their certification, innovation, and customer-first practices will be an invaluable partner in facilitating production processes and achieving operational success.

Assessing Reliability Reliability of supply chain performance also plays a key role in selecting a fiberglass tape supplier. Suppliers should exhibit a robust logistics framework, capable of ensuring timely deliveries and handling large volume demands efficiently. Evaluating their customer service response times and problem-resolution strategies can provide insights into their operational reliability. Building Trust through Transparency Trust in a supplier can be cultivated through their transparency in production processes and pricing. Trustworthy suppliers offer comprehensive product data sheets, openly share their supply chain processes, and provide clear, no-hidden-fees pricing models. Transparent practices allow businesses to forecast expenses accurately and plan procurement without unexpected financial hiccups. Customer Testimonials and Reviews Exploring customer reviews and testimonials provides a deeper understanding of a supplier's market reputation. Feedback from other businesses can shed light on the quality of the products, the supplier’s service response times, and overall customer satisfaction. Engaging with a supplier’s existing customers if possible can offer candid insights that aren’t always captured in written reviews. In summary, selecting a fiberglass tape supplier involves assessing their expertise, reliability, and trustworthiness. By focusing on these elements, businesses can ensure a steady supply of high-quality materials that meet project requirements and industry standards. A supplier that exhibits authority in the field through their certification, innovation, and customer-first practices will be an invaluable partner in facilitating production processes and achieving operational success.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories