1 月 . 15, 2025 09:20 Back to list

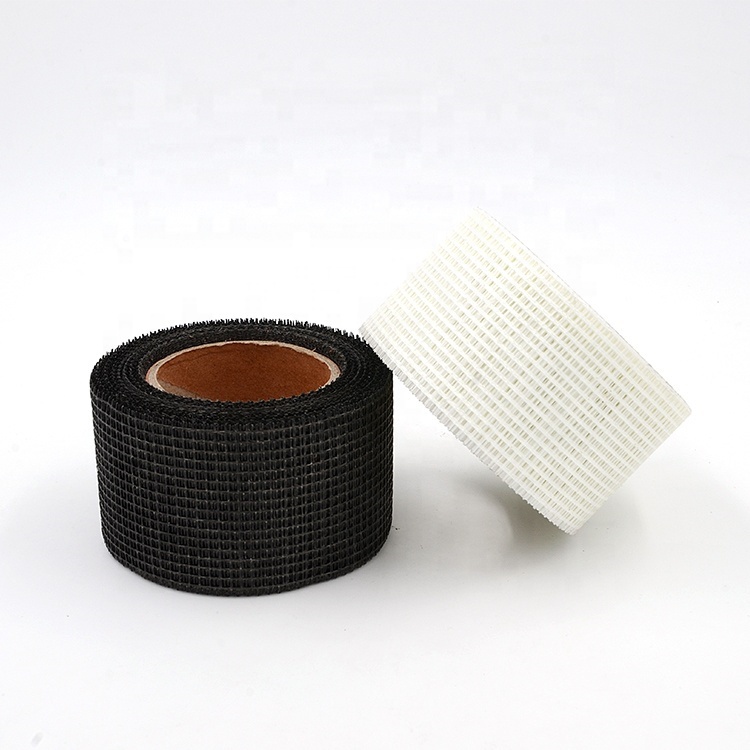

fiberglass mesh for concrete

Fiberglass mesh stands as a critical component in modern construction, offering much more than just a reinforcement option for concrete. Over the years, its utilization has soared, thanks to its properties which translate into long-term benefits for infrastructure projects. Its integration into the construction field reflects significant experience and expertise, adding credible authority and trustworthiness to the solutions it provides.

The authoritative inclusion of fiberglass mesh in building codes globally speaks to its trustworthiness as a product. Engineers and architects increasingly recommend fiberglass mesh, confident in its proven track record in safety and durability tests. Moreover, environmental consideration plays a pivotal role; fiberglass mesh is a non-toxic, inert product, adding a layer of sustainability to its appeal. To maintain the cutting edge of fiberglass mesh use in concrete, ongoing research and development are producing enhanced versions, tailored to meet specific construction demands and eco-friendly benchmarks. Specialists in the field emphasize its performance in seismic zones, where flexibility and resilience are non-negotiable factors. This focus reassures stakeholders within the construction industry of fiberglass mesh’s ability to meet evolving architectural challenges. In conclusion, fiberglass mesh for concrete is a pillar of modern construction innovation. Offering unparalleled strength, longevity, and cost-effectiveness, along with environmental benefits, it captures the essence of a trusted, expert solution. With its rise in acceptance and continued endorsement by construction professionals, fiberglass mesh is not just a choice but a necessity for contemporary concrete applications.

The authoritative inclusion of fiberglass mesh in building codes globally speaks to its trustworthiness as a product. Engineers and architects increasingly recommend fiberglass mesh, confident in its proven track record in safety and durability tests. Moreover, environmental consideration plays a pivotal role; fiberglass mesh is a non-toxic, inert product, adding a layer of sustainability to its appeal. To maintain the cutting edge of fiberglass mesh use in concrete, ongoing research and development are producing enhanced versions, tailored to meet specific construction demands and eco-friendly benchmarks. Specialists in the field emphasize its performance in seismic zones, where flexibility and resilience are non-negotiable factors. This focus reassures stakeholders within the construction industry of fiberglass mesh’s ability to meet evolving architectural challenges. In conclusion, fiberglass mesh for concrete is a pillar of modern construction innovation. Offering unparalleled strength, longevity, and cost-effectiveness, along with environmental benefits, it captures the essence of a trusted, expert solution. With its rise in acceptance and continued endorsement by construction professionals, fiberglass mesh is not just a choice but a necessity for contemporary concrete applications.

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories