1 月 . 15, 2025 09:21 Back to list

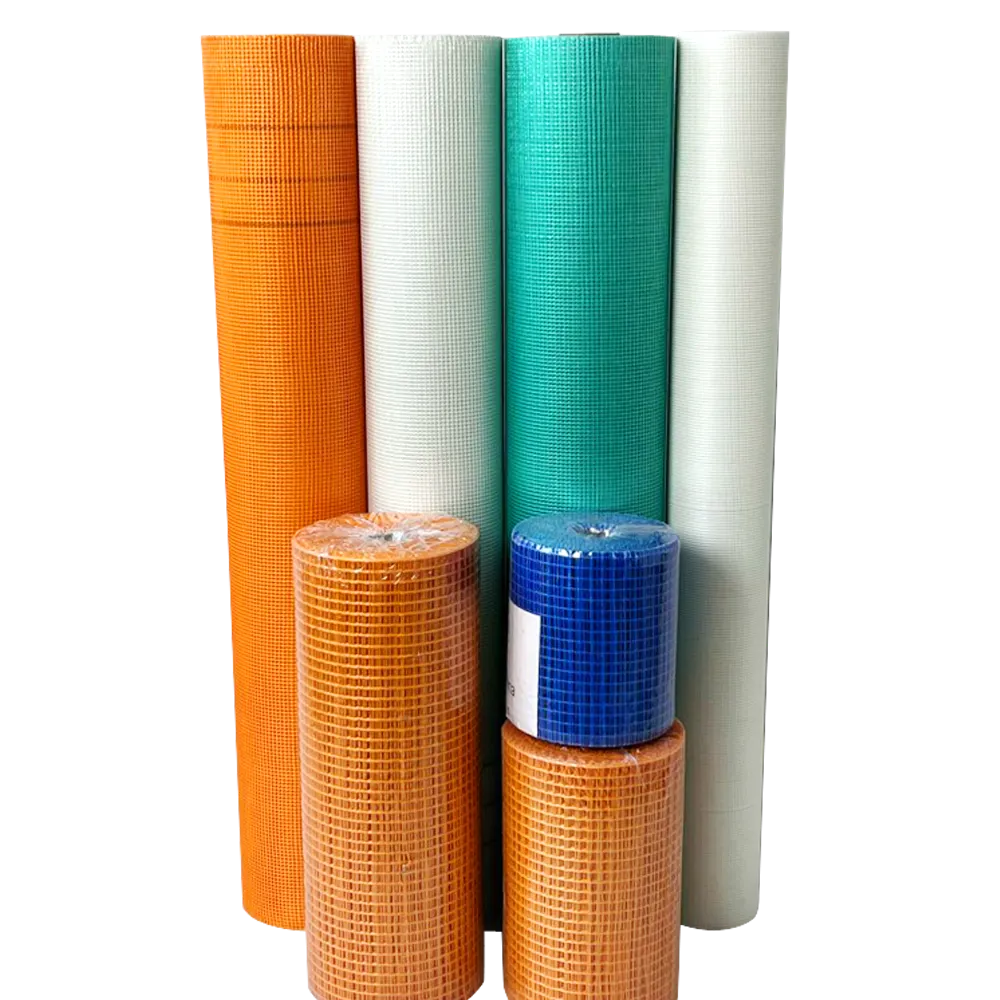

fiberglass mesh in concrete

Fiberglass mesh in concrete has revolutionized the construction industry, providing a robust solution that enhances both the structural integrity and longevity of concrete applications. This innovation represents a significant leap forward in construction technology, offering unparalleled benefits over traditional reinforcement materials.

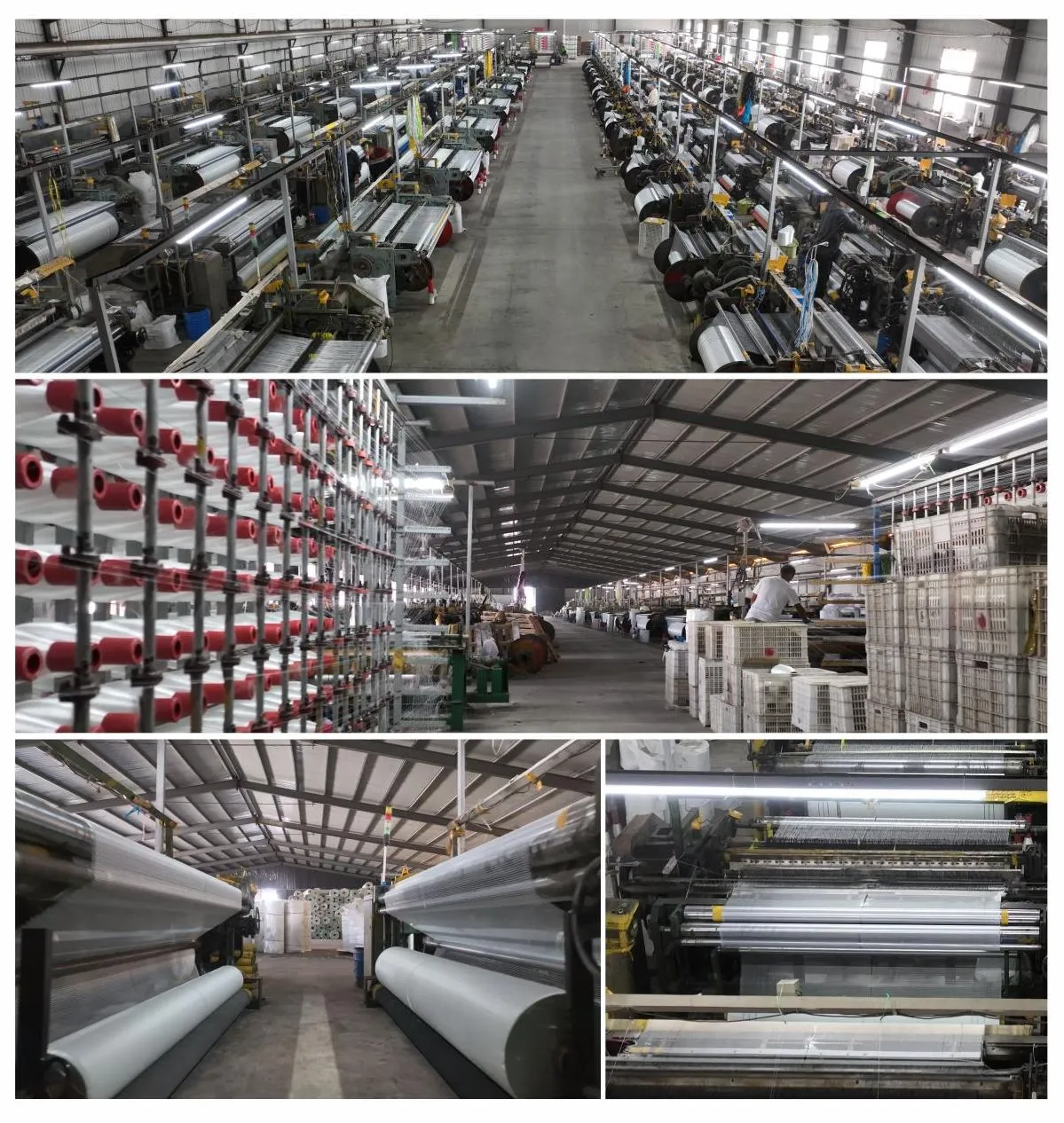

As an authoritative figure in the field, one must keep abreast of technological advancements and evolving best practices. Continuous education in the latest fiberglass manufacturing techniques and the development of eco-friendly variants bolster one's ability to provide sustainable building solutions. Engaging with peer-reviewed journals, attending industry conferences, and holding certifications from recognized construction bodies enhance credibility and foster trust among clients seeking reliable construction partners. The trustworthiness of fiberglass mesh in concrete applications stems from its proven track record across numerous projects worldwide. Builders and architects have turned to fiberglass mesh for its consistent performance in seismic zones and regions prone to soil movement. By minimizing the risk of concrete shifting or cracking, fiberglass mesh helps maintain the aesthetic and functional value of a structure over time. The trust garnered from successful applications of fiberglass mesh is further amplified by manufacturers committed to quality assurance and rigorous testing. Reputable suppliers adhere to international standards, offering detailed product specifications and usage guidelines. This level of transparency helps construction experts make informed decisions, ensuring that their projects stand the test of time. In conclusion, fiberglass mesh is not merely an alternative to traditional concrete reinforcements; it is a transformative component that elevates construction standards. Professionals in the industry recognize its ability to deliver sustainable, long-lasting, and reliable results. As a product, fiberglass mesh embodies the ideals of innovation and resilience, positioning it as a forward-thinking choice for modern construction needs. Through its continued endorsement and integration within the construction community, fiberglass mesh in concrete sets new benchmarks for excellence in building technology.

As an authoritative figure in the field, one must keep abreast of technological advancements and evolving best practices. Continuous education in the latest fiberglass manufacturing techniques and the development of eco-friendly variants bolster one's ability to provide sustainable building solutions. Engaging with peer-reviewed journals, attending industry conferences, and holding certifications from recognized construction bodies enhance credibility and foster trust among clients seeking reliable construction partners. The trustworthiness of fiberglass mesh in concrete applications stems from its proven track record across numerous projects worldwide. Builders and architects have turned to fiberglass mesh for its consistent performance in seismic zones and regions prone to soil movement. By minimizing the risk of concrete shifting or cracking, fiberglass mesh helps maintain the aesthetic and functional value of a structure over time. The trust garnered from successful applications of fiberglass mesh is further amplified by manufacturers committed to quality assurance and rigorous testing. Reputable suppliers adhere to international standards, offering detailed product specifications and usage guidelines. This level of transparency helps construction experts make informed decisions, ensuring that their projects stand the test of time. In conclusion, fiberglass mesh is not merely an alternative to traditional concrete reinforcements; it is a transformative component that elevates construction standards. Professionals in the industry recognize its ability to deliver sustainable, long-lasting, and reliable results. As a product, fiberglass mesh embodies the ideals of innovation and resilience, positioning it as a forward-thinking choice for modern construction needs. Through its continued endorsement and integration within the construction community, fiberglass mesh in concrete sets new benchmarks for excellence in building technology.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories