2 月 . 02, 2025 00:56 Back to list

fiberglass mesh for plastering pricelist

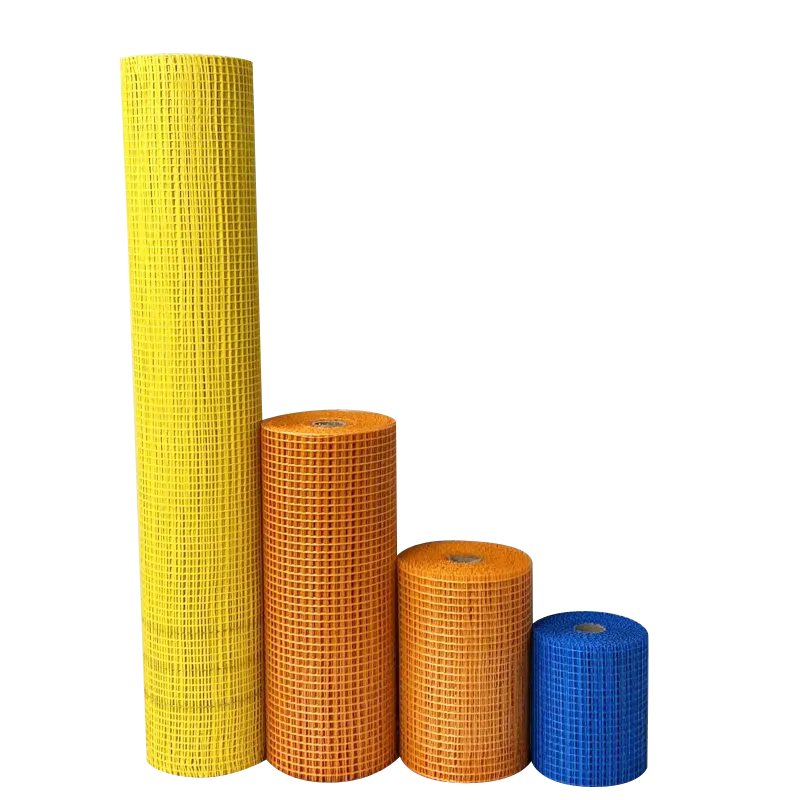

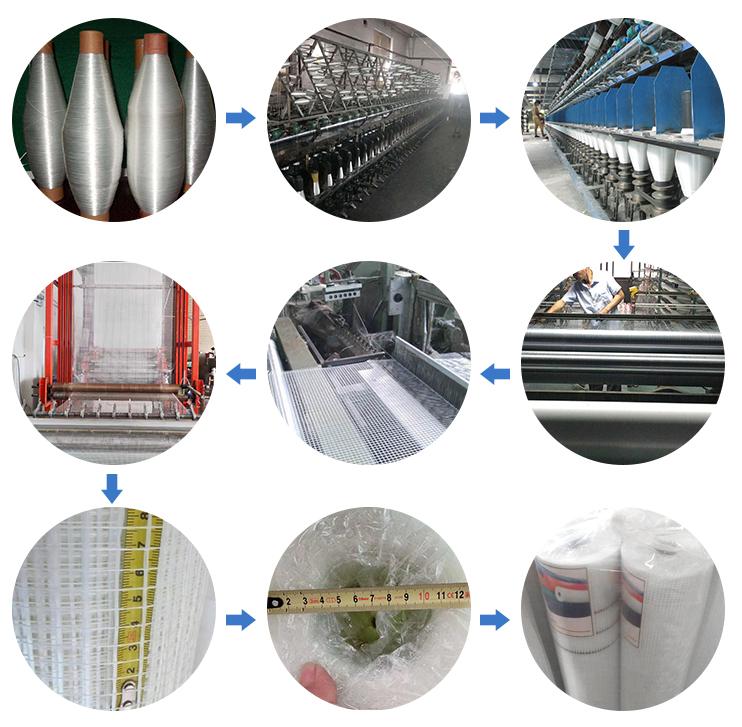

Fiberglass mesh has emerged as an essential component in the construction and renovation industry, especially for plastering applications. Its use has been gaining traction due to its impressive strength, versatility, and cost-effectiveness. When considering fiberglass mesh for plastering, understanding its price and value is crucial for both professionals and DIY enthusiasts. This guide delves into what makes fiberglass mesh an invaluable asset in plastering and provides insight into its pricing.

As with many other construction products, bulk purchasing fiberglass mesh directly from a manufacturer or authorized distributor can lead to significant cost savings. Suppliers who offer competitive pricelists often provide additional services such as customized sizes and coatings, ensuring that each project receives a tailored solution. Negotiating terms such as delivery options, payment conditions, and after-sales support can also enhance the value obtained from the purchase. Another critical aspect of pricing involves the projected lifecycle cost. While initial outlay is a consideration, the long-term savings derived from using high-quality fiberglass mesh can be substantial. Reduced maintenance, improved longevity, and sustained structural integrity mean that the investment often pays for itself over time. For businesses, this translates to a lower total cost of ownership, adding to the overall profitability of using fiberglass mesh in construction. Building trust with suppliers and understanding the intricate details of fiberglass mesh products lay the foundation for making informed purchasing decisions. The right mesh can dramatically enhance the quality and durability of plastering work, making it a staple in the toolkit of construction professionals. Balancing cost with performance ensures that fiberglass mesh remains a wise choice for achieving superior plaster finishes, reinforcing its position as a trusted material in the industry. Real-world experiences and testimonials from seasoned construction professionals further validate the value of fiberglass mesh. Many report not only the ease of application but also the enhanced performance in comparison to traditional reinforcement methods. Such endorsements from industry veterans add a layer of credibility that reinforces the reliability and indispensability of fiberglass mesh in modern construction practices. In conclusion, understanding the pricing and application of fiberglass mesh for plastering involves evaluating the quality, certification, and suitability for specific projects. Combining expert advice with a strategic approach to purchasing can lead to substantial benefits, ensuring successful outcomes in any plastering endeavor.

As with many other construction products, bulk purchasing fiberglass mesh directly from a manufacturer or authorized distributor can lead to significant cost savings. Suppliers who offer competitive pricelists often provide additional services such as customized sizes and coatings, ensuring that each project receives a tailored solution. Negotiating terms such as delivery options, payment conditions, and after-sales support can also enhance the value obtained from the purchase. Another critical aspect of pricing involves the projected lifecycle cost. While initial outlay is a consideration, the long-term savings derived from using high-quality fiberglass mesh can be substantial. Reduced maintenance, improved longevity, and sustained structural integrity mean that the investment often pays for itself over time. For businesses, this translates to a lower total cost of ownership, adding to the overall profitability of using fiberglass mesh in construction. Building trust with suppliers and understanding the intricate details of fiberglass mesh products lay the foundation for making informed purchasing decisions. The right mesh can dramatically enhance the quality and durability of plastering work, making it a staple in the toolkit of construction professionals. Balancing cost with performance ensures that fiberglass mesh remains a wise choice for achieving superior plaster finishes, reinforcing its position as a trusted material in the industry. Real-world experiences and testimonials from seasoned construction professionals further validate the value of fiberglass mesh. Many report not only the ease of application but also the enhanced performance in comparison to traditional reinforcement methods. Such endorsements from industry veterans add a layer of credibility that reinforces the reliability and indispensability of fiberglass mesh in modern construction practices. In conclusion, understanding the pricing and application of fiberglass mesh for plastering involves evaluating the quality, certification, and suitability for specific projects. Combining expert advice with a strategic approach to purchasing can lead to substantial benefits, ensuring successful outcomes in any plastering endeavor.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories