2 月 . 02, 2025 01:18 Back to list

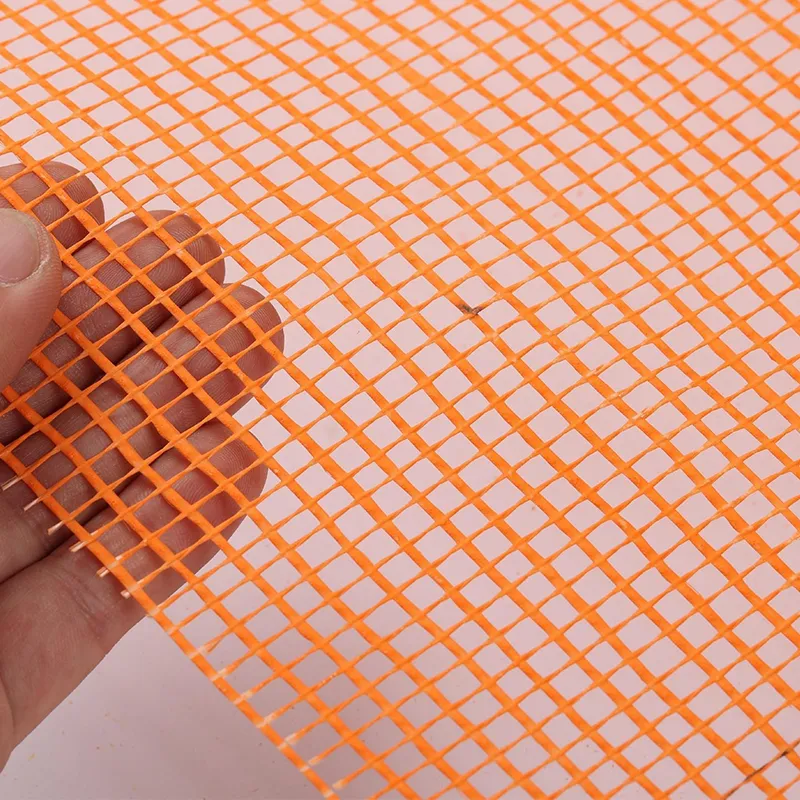

fiberglass mesh for plastering companies

In the world of construction and renovation, the choice of materials can make a significant difference in the durability and quality of the finished product. One such material that has earned a reputation for its effectiveness is fiberglass mesh, particularly in plastering applications. Companies specializing in plastering have increasingly turned to fiberglass mesh due to its array of benefits, which not only enhance the plastering process but also improve the longevity and resilience of the walls.

In terms of authoritativeness, the manufacturing process of fiberglass mesh adheres to stringent industry standards to ensure optimal performance. Renowned manufacturers implement rigorous quality control measures that guarantee consistency in product quality. Leading brands within the industry also offer certifications, which plastering companies can leverage to assure clients of the material's reliability and safety. This certification serves as a testament to its efficacy, reinforcing the trust between the contractor and the client. Fiberglass mesh also promotes environmental sustainability, aligning with modern construction practices. The production of fiberglass mesh requires less energy compared to traditional metal mesh, reducing the overall carbon footprint of a construction project. Companies that prioritize eco-friendly practices often choose fiberglass mesh as it contributes to green building certifications and initiatives, further cementing its status as a preferred choice among industry professionals. However, expertise in handling fiberglass mesh is required to maximize its benefits. Skilled labor is necessary to accurately cut and fit the mesh to the specific dimensions of the plastered area. Incorrect installation can lead to subpar results, so training and experience in working with this material are essential. Companies that invest in workforce training can ensure that their team is well-equipped to deliver high-quality results, enhancing their reputation in the field. In conclusion, fiberglass mesh presents an invaluable tool for plastering companies aiming to deliver superior quality and durability in their projects. Its application not only prevents common plastering issues like cracking and shrinkage but also contributes to the overall sustainability and efficiency of construction projects. As more companies recognize the long-term benefits of integrating fiberglass mesh into their plastering processes, it solidifies its status as a cornerstone in modern construction practices. By continuing to share best practices and innovations surrounding fiberglass mesh, the industry can further enhance its effectiveness and reliability, ultimately benefiting both contractors and clients alike.

In terms of authoritativeness, the manufacturing process of fiberglass mesh adheres to stringent industry standards to ensure optimal performance. Renowned manufacturers implement rigorous quality control measures that guarantee consistency in product quality. Leading brands within the industry also offer certifications, which plastering companies can leverage to assure clients of the material's reliability and safety. This certification serves as a testament to its efficacy, reinforcing the trust between the contractor and the client. Fiberglass mesh also promotes environmental sustainability, aligning with modern construction practices. The production of fiberglass mesh requires less energy compared to traditional metal mesh, reducing the overall carbon footprint of a construction project. Companies that prioritize eco-friendly practices often choose fiberglass mesh as it contributes to green building certifications and initiatives, further cementing its status as a preferred choice among industry professionals. However, expertise in handling fiberglass mesh is required to maximize its benefits. Skilled labor is necessary to accurately cut and fit the mesh to the specific dimensions of the plastered area. Incorrect installation can lead to subpar results, so training and experience in working with this material are essential. Companies that invest in workforce training can ensure that their team is well-equipped to deliver high-quality results, enhancing their reputation in the field. In conclusion, fiberglass mesh presents an invaluable tool for plastering companies aiming to deliver superior quality and durability in their projects. Its application not only prevents common plastering issues like cracking and shrinkage but also contributes to the overall sustainability and efficiency of construction projects. As more companies recognize the long-term benefits of integrating fiberglass mesh into their plastering processes, it solidifies its status as a cornerstone in modern construction practices. By continuing to share best practices and innovations surrounding fiberglass mesh, the industry can further enhance its effectiveness and reliability, ultimately benefiting both contractors and clients alike.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories