2 月 . 02, 2025 01:35 Back to list

fiberglass mesh for plastering supplier

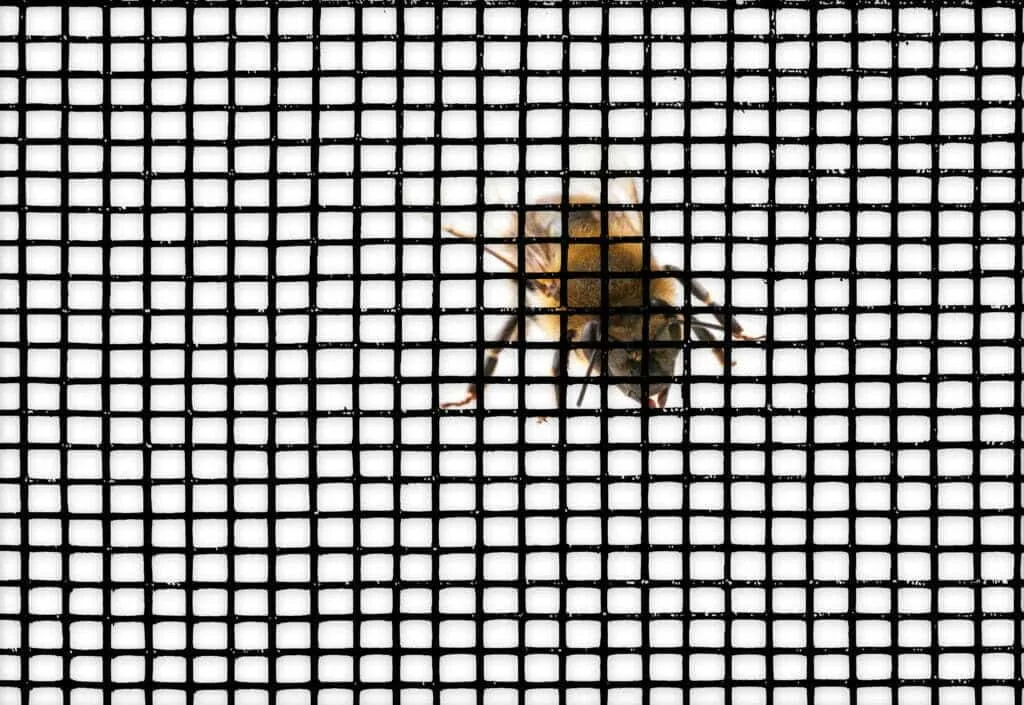

Fiberglass mesh is an integral component in modern plastering applications. As the construction industry advances, the demand for strong, durable, and effective materials has seen significant growth. Among these materials, fiberglass mesh stands out due to its versatility and strength, playing a vital role in ensuring the longevity and durability of plastered surfaces.

An experienced supplier will also be knowledgeable about environmental impact and sustainability. Users can trust that a leading supplier understands the importance of environmentally friendly practices and offers products that contribute to sustainable building practices. This includes utilizing biodegradable packaging and ensuring minimal wastage during production. Trustworthiness comes from consistent quality and accountability. A supplier that stands by their product will offer warranties and quality assurances, giving clients peace of mind that they are investing in reliable materials. Furthermore, knowledgeable suppliers often provide detailed usage instructions and support, assisting builders and contractors in making the most of the fiberglass mesh. This includes offering insights into working with different types of plaster and how to maximize the mesh's benefits in various conditions and applications. The innovation in fiberglass mesh technology has contributed to more efficient construction practices. Extensive research and development in this sector mean modern meshes can tolerate greater amounts of stress and provide added value to projects compared to older products. This is why staying updated with advancements and working with suppliers keen on innovation is vital for any construction business aiming to maintain a competitive edge. Ultimately, the right fiberglass mesh for plastering supplier will not only supply a product but will act as a partner in construction, providing the means to undertake projects with confidence in the materials' performance. Investing time in selecting a supplier skilled in experience, expertise, authoritativeness, and trustworthiness ensures the mesh plays a crucial role in maintaining the structural longevity of any building endeavor.

An experienced supplier will also be knowledgeable about environmental impact and sustainability. Users can trust that a leading supplier understands the importance of environmentally friendly practices and offers products that contribute to sustainable building practices. This includes utilizing biodegradable packaging and ensuring minimal wastage during production. Trustworthiness comes from consistent quality and accountability. A supplier that stands by their product will offer warranties and quality assurances, giving clients peace of mind that they are investing in reliable materials. Furthermore, knowledgeable suppliers often provide detailed usage instructions and support, assisting builders and contractors in making the most of the fiberglass mesh. This includes offering insights into working with different types of plaster and how to maximize the mesh's benefits in various conditions and applications. The innovation in fiberglass mesh technology has contributed to more efficient construction practices. Extensive research and development in this sector mean modern meshes can tolerate greater amounts of stress and provide added value to projects compared to older products. This is why staying updated with advancements and working with suppliers keen on innovation is vital for any construction business aiming to maintain a competitive edge. Ultimately, the right fiberglass mesh for plastering supplier will not only supply a product but will act as a partner in construction, providing the means to undertake projects with confidence in the materials' performance. Investing time in selecting a supplier skilled in experience, expertise, authoritativeness, and trustworthiness ensures the mesh plays a crucial role in maintaining the structural longevity of any building endeavor.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories